Multi-lane Cup Filler

Multi-lane Cup Filling-Sealing Machine

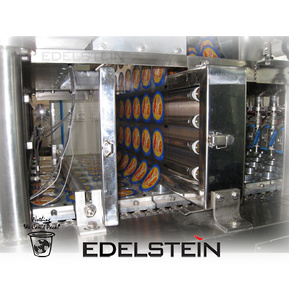

Rolled Foil Models

Pre-Form Foil Models

model: ED-MLC-201R

Multi-Lane Cup Filling-Sealing Machine

Rolled foil

for large cup (cup mouth Dia. larger than 50mm)

model: ED-MLC-202R

Multi-Lane Cup Filling-Sealing Machine

Rolled foil

for small cup (cup mouth Dia. smaller than 50mm)

model: ED-MLC-201P

Multi-Lane Cup Filling-Sealing Machine

Pre-form foil

for large cup (cup mouth Dia. larger than 50mm)

model: ED-MLC-202P

Multi-Lane Cup Filling-Sealing Machine

Pre-form foil

for small cup (cup mouth Dia. smaller than 50mm)

Cup Rinsing System

Water Cup Washing System

Air Cup Washing System

Foil Sterlization System

Multi-line design for plastic container like cup, tray to filling powder, liquid, viscosity for food packaging, dairy packaging , hardware products packaging application. Custom design is available for individual application.

Final Product Discharge Devices:

Cup Filler Sealer

Model: ED-MLC201S-8P

Multi-Lane Coffee Powder Filling & Sealing machine

The ED-MLC-201-6 is uniquely designed for drip cup coffee. The machine unit container loading, bottom filter paper loading-sealing, servo-control coffee powder loading, top filter paper loading-sealing and final cup discharging with conveyor as complete system. Various production required is available with custom size and demand.

Cup water filling-sealing machine for Cup Drinking Water

Model: ED-MLC201-4R

Speed: 80 cups/min

with options exit collector and delivery conveyor 2m.

More model is available upon request

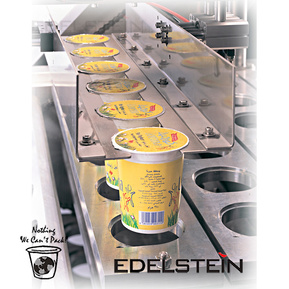

Multi-Lane Cup Filling-Sealing Machine with Cup Washing System

Model: ED-MLC201-8P

Multi-Lane cup filling-sealing machine is specially designed for cup water, cup juice application.

With cup washing system to clean ready-made cup before filling to ensure cup totally sanitary.

HEPA on filling chamber

Exit horizontal discharging system with necessary conveyor as a automation is available upon request.

More model is available upon request

Multi-lane cup filling-Sealing Machine for Cup Juice Line

Model: ED-MLC201-8R

Speed: 160 cups/min

Cup filling-Sealing machine including cup washing system in front of filling mechanism and exit cup collector to pick up sealed cup into cup Warmer-Cooler for complete sterilizing process

More model is available upon request

Multi-Lane Cup/Tray Sealing-Filling Machines

Multi-lane cup/tray sealing-filling machines with heat sealing function are advanced packaging systems designed to efficiently seal and fill multiple cups or trays simultaneously. The following technical essay aims to provide a comprehensive overview of these machines, including their features, characteristics, functions, operation, advantages, and limitations. With their high-speed production capabilities and integrated sealing and filling functions, multi-lane machines are well-suited for high-volume packaging operations in various industries.

Features:

- Multi-Lane Configuration: These machines feature multiple lanes or tracks, allowing for parallel sealing and filling of multiple cups or trays simultaneously.

- High-Speed Production: Designed for high-volume production, multi-lane machines offer fast and efficient packaging processes, maximizing productivity.

- Customizable Design: The machines can be tailored to accommodate different lane configurations and meet specific production requirements.

- Integration Capabilities: Multi-lane machines often incorporate additional functions such as filling, labeling, and capping to streamline the packaging process.

- Versatile Compatibility: They can handle a wide range of cup and tray sizes, materials, and product types, providing flexibility in packaging options.

Characteristics:

- Lane-based Operation: Each lane operates independently, allowing for simultaneous sealing and filling operations.

- Precise Sealing Control: Advanced sensors and controls ensure accurate sealing parameters, such as temperature, pressure, and sealing time, for consistent and reliable results.

- Efficient Material Handling: Integrated conveyors or indexing systems transport cups or trays through the lanes smoothly and precisely.

- Automated Functions: Multi-lane machines often feature automated cup or tray feeding, filling, and sealing processes, minimizing manual intervention.

Functions:

- Sealing: The machines employ heat sealing technology to create secure and airtight seals on cups or trays. Precise control of sealing parameters ensures consistent and reliable sealing quality.

- Filling: Integrated filling systems accurately dispense the desired quantity of product into each cup or tray, ensuring precise and consistent filling levels.

- Capping (optional): Some multi-lane machines can incorporate capping stations to apply caps or lids onto sealed cups or trays, providing complete packaging solutions.

Operation:

- Cup/Tray Feeding: Cups or trays are automatically fed into each lane through a conveyor system or indexing mechanism.

- Sealing and Filling: Each lane operates independently to seal and fill the cups or trays. Heat sealing mechanisms create secure seals, while filling systems dispense the desired product quantity.

- Discharge and Packaging: Sealed and filled cups or trays are discharged from each lane for further processing, such as labeling, cartoning, or palletizing.

Advantages:

- Increased Productivity: Multi-lane machines can handle multiple cups or trays simultaneously, resulting in higher production rates and improved efficiency.

- Space and Labor Savings: By consolidating sealing and filling operations into a single machine, multi-lane systems reduce the need for multiple machines and operators, saving valuable space and labor costs.

- Enhanced Process Control: Advanced sensors and controls ensure consistent sealing and filling parameters, minimizing product wastage and ensuring product integrity.

- Versatility and Customization: Multi-lane machines can accommodate various cup and tray sizes, materials, and product types, providing flexibility in packaging options.

- Streamlined Workflow: Integration of sealing, filling, and optional capping functions simplifies the packaging process and reduces the need for additional equipment.

Limitations:

- Initial Investment: Multi-lane machines typically involve higher initial capital costs compared to single-lane or manual machines.

- Complexity: These machines require proper setup, calibration, and maintenance. Skilled operators are necessary to ensure optimal performance.

- Changeover Time: Adjustments and changeovers may be required

Applications:

What are the most popular applications of Cup Packaged goods with Multi-Lane Cup Filler-Sealer?

The high productivity requirement of food, beverage, sweets production line are are the most popular to use Multi-Lane Cup Filler-Sealer.

Cups and trays are common packaging formats for a wide range of products across various industries. Here are some examples:

- Food: Tofu (soybean curd), yogurt, pudding, fruit cups, jelly, sauces, dips, soups, noodles, salads, snack cups, butter, honey, jam, bakery products, etc.

- Beverage: water, juice, tea, coffee, smoothies, iced drinks, energy drinks, ice cube etc.

- Sweets: jelly, pudding, candies, chocolates, gummies, mints, etc.

- Daily chemicals: liquid soaps, shampoos, conditioners, lotions, creams, etc.

- Pharmaceutics: tablets, capsules, powders, syrups, etc.

- Cosmetics and personal care: lip balms, mascaras, eyeliners, nail polish, hair dye, etc.

“Looking for a Packaging machine”?

Just contact “Edelstein International Co., Ltd.”

You will find “Nothing we can’t Pack!”

EDELSTEIN INTERNATIONAL CO., LTD.

No. 396 Ta-tun 11th Street. Taichung 408, Taiwan

Tel: 886-4-22.51.55.06

Fax: 886-4-22.56.93.69

edel@ms36.hinet.net

• • •