HOME > Bottling

Bottling

Our Bottling production line equipment (Bottling Line Machines) covers Bottle Unscrambling Machines, Bottle Rinsing Machines, Bottle Filling Machines, Bottle Capping Machines, Bottle Aluminum Foil Sealing Machines, Cap Sorting Machines, Bottle Warming Machines.

Bottling Lines

Comprehensive Bottling Line for Various Industrial Applicatoins and Products

Bottling Machines

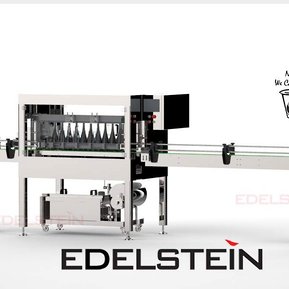

Monoblock Bottling Machines

2in1, 3in1, 4in1

Click Bottling Machines to check the all bottling machines!

If you are not sure which type you should select or you need professionally technical consultation, please contact us, we will provide you with the most suitable solution according to your actual needs.

Brief Processing Workflow of Bottling Line:

Introduction to Bottling Lines

A bottling line is a complex system of machines that are used to fill and package various types of beverages, including carbonated and soft drinks, beer, wine, and spirits. The bottling line is typically made up of various individual equipment or machines that work together to fill, cap, and label bottles at a high speed and with high precision. In this article, we will discuss the various functions, features, and types of individual equipment that are commonly found in a bottling line.

Functions and Features of a Bottling Line

The main function of a bottling line is to take empty bottles, fill them with a product, cap them, and label them for sale. The bottling line must also be able to inspect the bottles for defects and remove any bottles that do not meet quality standards. Additionally, bottling lines must be designed to work efficiently and quickly, with minimal downtime and maximum output.

To achieve these functions, bottling lines typically include various types of individual equipment or machines, which we will discuss below.

Individual Equipment (Machines) in a Bottling Line

A bottle unscrambler (bottle sorter, bottle sorting machine) is a machine that is used to orient and feed empty bottles into the bottling line. The unscrambler separates the bottles, and orients them correctly so that they can be transported to the next stage of the process.

Bottle Air Rinsing

Bottle Water Rinsing

The bottle rinser is used to clean the bottles before they are filled. The bottles are filled with a cleaning solution and then rinsed with water to remove any remaining residue or contaminants.

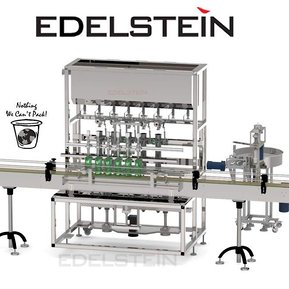

The bottle filler is one of the most important machines in the production line. It is used to fill the bottles with the product, whether carbonated soft drinks, beer, wine, or spirits. Filling machines are designed to work quickly and efficiently while maintaining precise fill levels and preventing spills or leaks.

After the bottles are filled, they are capped with a machine called a capper (bottle capping machine). There are various types of cappers, including screw-on cappers, snap-on cappers, and corkers, depending on the type of bottle and product being packaged.

Some bottles require a seal around the cap to ensure that they are properly closed and to prevent any leaks. Sealing machines are used to apply a tamper-evident seal or sleeve to the bottle.

Step 5

Bottle Labeling

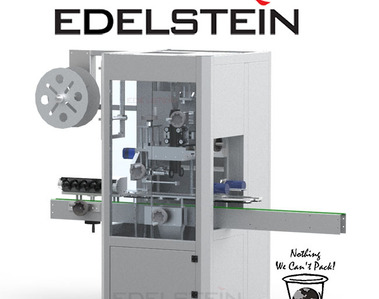

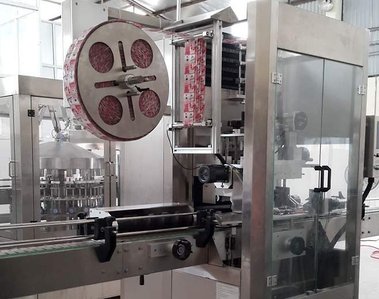

Finally, labeling machines are used to apply labels to the bottles. There are various types of labeling machines, including pressure-sensitive labeling machines, roll-fed labeling machines, and hot melt glue labeling machines.

Step 6

Bottle Wrapping / Bottle Palletizing

A comprehensive models of Bottle Wrapping / Bottle Palletizing are available for your different applications and production requirement.

If you are not sure which type you should or you need professionally technical consultation, please contact us, we will provide you with the most suitable solution according to your actual needs.

Bottling lines are complex systems of machines that work together to fill, cap, and label bottles for sale. The individual machines in a bottling line must be designed to work efficiently and quickly, while also maintaining the correct levels of quality and accuracy. By understanding the various types of machines used in a bottling line, you can better understand the process of packaging your favorite beverages.

Here are some common essential equipment that are often included in a bottle packaging turnkey line:

- Bottle Unscrambler: This equipment is used to sort and orient bottles before they are filled. It can handle bottles of different sizes and shapes, and is designed to work with high-speed filling lines.

- Bottle Rinser: This equipment is used to clean the inside of the bottle before filling. It can use different cleaning methods, such as air, water or steam, depending on the type of beverage being packaged.

- Conveyors: These are used to transport bottles between different stages of the packaging line. They can be designed to handle different types of bottles and can be customized to fit the layout of the packaging facility.

- Filling Machines: These are used to accurately fill the bottles with the beverage. There are several types of filling machines, including gravity fillers, piston fillers, vacuum fillers, and isobaric fillers.

- Capping Machines: These are used to seal the bottles with a cap or a lid. There are different types of capping machines, such as screw cappers, snap cappers, and crimp cappers.

- Labeling Machines: These are used to apply labels to the bottles. There are different types of labeling machines, such as pressure sensitive labelers, hot melt glue labelers, and sleeve labelers.

- Inkjet Coders: These are used to print batch numbers, expiry dates, and other information on the bottles.

- Case Packers: These are used to pack the filled and capped bottles into cases for transport.

- Palletizers: These are used to stack the cases onto pallets for transport.

- Inspection Machines: These are used to inspect the filled and capped bottles for defects, such as cracks or chips, and to ensure that they are filled to the correct level.

Each of these auxiliary equipment can be customized to fit the specific needs of the beverage production facility, and can be integrated into a turnkey packaging line to ensure maximum efficiency and productivity.

More Supporting Machines are available!

If you are not sure which type you should or you need professionally technical consultation, please contact us, we will provide you with the most suitable solution according to your actual needs.

HOME > Bottling

“Looking for a Packaging machine”?

Just contact “Edelstein International Co., Ltd.”

You will find “Nothing we can’t Pack!”

EDELSTEIN INTERNATIONAL CO., LTD.

No. 396 Ta-tun 11th Street. Taichung 408, Taiwan

Tel: 886-4-22.51.55.06

Fax: 886-4-22.56.93.69

edel@ms36.hinet.net

• • •