Home > Sorting > Bottle Sorting > Centrifugal Bottle Unscrambler

Centrifugal Bottle Unscrambling Machine

Bottle Sorter

Bottle Sort, Orient and Feed

Centrifugal Bottle Unscrambler

Centrifugal with cave bottle unscrambler including integrated bottle storage tank, sorter and orientation feeder made by Edelstein to coordinate with related filling & capping systems as a automaton line. The centrifugal unscrambling machine is equipped with a optional vacuum system on feeding mechanism especially to have much stable loading motion for light PET bottle in high speed movement. Easy change over design is friendly adjusting for different bottle width with less exchanging time and lower skill difficulty required and is ideal to be applied in the field of Beverage, Chemicals, Cosmetics, Beauty and Household products.

This Centrifugal Bottle unscrambler with bottle storage tank, sorter and orientation feeder made by Edelstein to coordinate with related filling, sealing & capping systems as a automaton bottling line to be applied in the field of Beverage, Chemicals, Cosmetics, Beauty and Household products.

A versatile range of bottle unscramblers that allow multiple container formats to be carefully sorted and orientated in a single machine system.

EDELSTEIN'S bottle unscrambling machines (Bottle Sorting Machines) are designed to offer an perfect combination of quality, reliability and precision.

The complete bottle unscrambler indcluding:

- Cotainer Storage Tank with orintation function

- Bottle Feeding conveyor

- Bottle Sorting device

- Bottle discharge deivce

Applications of the complete range of various type of bottles:

- Softdrink Bottles

- Food stuff Bottles

- Personal care products

- Hygienic containers

Centrifugal Bottle Unscrambler:

A centrifugal bottle unscrambler is a type of bottle sorting and orienting machine used in packaging lines to efficiently feed and align bottles before further processing. It utilizes centrifugal force to separate and orient bottles from a bulk supply, ensuring a continuous and controlled flow of bottles.

Operation:

- Bottle Loading: Bottles are loaded into a bulk supply hopper or container.

- Centrifugal Force: The unscrambler employs a spinning disc or rotating wheel to create centrifugal force.

- Bottle Separation: As the disc or wheel spins, the centrifugal force separates the bottles, causing them to move outward along individual tracks or channels.

- Bottle Orientation: The bottles undergo orientation as they move along the tracks or channels, aligning them in the desired position.

- Bottle Delivery: The oriented bottles are transferred to the packaging line for further processing.

Advantages:

- High-Speed Operation: Centrifugal bottle unscramblers can handle a large volume of bottles per minute, making them ideal for high-speed packaging lines.

- Continuous Operation: They offer a continuous flow of bottles, ensuring a smooth and uninterrupted production process.

- Versatility: Centrifugal unscramblers can handle various bottle sizes and shapes, providing flexibility for different packaging applications.

Limitations:

- Changeover Time: Switching between different bottle sizes or shapes may require adjustments to the machine, resulting in increased changeover time.

- Bottle Stability: Some centrifugal unscramblers may have limitations when handling unstable or lightweight bottles, requiring additional considerations to ensure proper orientation and transfer.

Orientation Concept:The centrifugal bottle unscrambler uses the combination of centrifugal force and carefully designed tracks or channels to separate and orient bottles. The spinning disc or rotating wheel creates the necessary force to separate the bottles and push them along the individual tracks or channels. Adjustable guides and mechanisms within the unscrambler help ensure that the bottles are properly oriented before being transferred to the packaging line.

Overall, the centrifugal bottle unscrambler is a reliable and efficient solution for bottle orientation and feeding, particularly in high-speed packaging lines. Its ability to provide a continuous flow of bottles and handle various sizes and shapes makes it well-suited for a wide range of packaging applications, streamlining the bottle handling process and improving overall productivity.

Centrifugal Bottle Unscrambler: Streamlining Bottle Packaging

We we take pride in offering cutting-edge packaging solutions for your business needs. We would like to introduce you to the centrifugal type bottle unscrambler, a highly efficient and versatile machine designed to streamline the bottle packaging process. With its innovative rotating star wheel system, the centrifugal bottle unscrambler ensures smooth and automated bottle feeding, optimizing productivity and reducing labor costs. Let's delve into the features, benefits, and applications of this impressive machine.

Efficient Bottle Unscrambling:

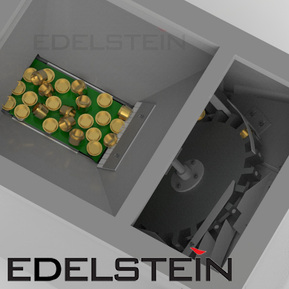

The centrifugal bottle unscrambler incorporates a rotating star wheel, also known as a rotary disc, equipped with bottle cavities. As bottles are fed into the machine's bulk storage tank, the star wheel effortlessly grabs each bottle and guides it to the designated position for further processing. This automated and continuous motion ensures a steady supply of bottles, eliminating the need for manual handling and minimizing downtime during production.

Key Features of the Centrifugal Bottle Unscrambler:

Rotary Disc System: The heart of the machine, the rotary disc, features precisely positioned bottle cavities that secure bottles in an upright position, ready for downstream operations.

Adjustable Bottle Cavities: The machine offers flexibility to accommodate various bottle sizes and shapes by easily adjusting the bottle cavities on the rotary disc.

Smooth Bottle Transfer: The star wheel mechanism smoothly transfers bottles from the bulk storage tank to the production line, ensuring a seamless transition.

High-Speed Operation: The centrifugal bottle unscrambler operates at high speeds, allowing for rapid bottle unscrambling and increased production efficiency.

User-Friendly Interface: The machine is equipped with an intuitive control panel, allowing operators to monitor and adjust settings with ease.

Benefits of Using a Centrifugal Bottle Unscrambler:

Increased Efficiency: By automating the bottle unscrambling process, the machine significantly reduces manual labor and improves overall production efficiency.

Enhanced Productivity: The continuous bottle feeding mechanism ensures a steady supply of bottles, minimizing downtime and optimizing output.

Improved Bottle Handling: The gentle bottle handling mechanism of the centrifugal unscrambler minimizes the risk of bottle damage or scuffing, maintaining product integrity.

Versatile Bottle Compatibility: The machine can accommodate various bottle sizes, shapes, and materials, offering versatility for different packaging requirements.

Space-Saving Design: The compact footprint of the centrifugal bottle unscrambler makes it an ideal choice for facilities with limited space.

Cost Savings: With increased automation and reduced labor requirements, businesses can achieve significant cost savings over time.

Applications of Centrifugal Bottle Unscramblers:

The centrifugal bottle unscrambler finds extensive application across industries that require efficient and precise bottle packaging. Some common applications include:

Beverage Industry: Unscrambling bottles for filling carbonated drinks, juices, water, energy drinks, and other beverage products.

Food Industry: Sorting and unscrambling bottles for sauces, dressings, condiments, oils, and other food products.

Pharmaceutical Industry: Preparing bottles for packaging medications, syrups, vitamins, and healthcare products.

Personal Care Industry: Unscrambling bottles for shampoos, lotions, creams, and cosmetic products.

Chemical Industry: Sorting and unscrambling bottles for chemicals, cleaning agents, and household products.

Conclusion:

The centrifugal type bottle unscrambler offers a reliable and efficient solution for the unscrambling and feeding of bottles in various industries. With its innovative rotating star wheel mechanism, adjustable bottle cavities, and user-friendly operation, this machine streamlines the packaging process, increases productivity, and ensures smooth bottle handling. Consider incorporating a centrifugal bottle unscrambler into your production line to optimize efficiency and take your packaging capabilities to new heights. Contact us today to learn more about how this remarkable machine can benefit your business.

Why is the bottle uncsrambler necessary used for bottling line?

Aiming at the demand of bottle unscrambling machine, this is because in the process of bottling production line, the empty bottles will be put into the production process of bottle rinsing, filling and capping first, but usually the empty bottles enter the filling machine and capping machine through the conveyor The state of these bottles conveyed into these bottling machines are accepted as specific position and orientation, at least the bottles must be standing instead of dumped and scattered on the conveyor belt. However, a large amount of empty bottles will be manually placed and stood on the conveyor belt, which is indeed a very large manpower load. Therefore, if the normal production speed is used, the automatic bottle unscrambling method will be adopted instead of manual placement, so that the whole batch of scattered bottles can be automatically and sequentially stood on the conveyor belt through the automatic bottle unscrambling machine. The sequence enters into the bottle washing machine, filling machine, capping machine and other bottle equipment for production.

Are you intertested in Acuumulation Tables?

Home > Sorting > Bottle Sorting > Centrifugal Bottle Unscrambler

“Looking for a Packaging machine”?

Just contact “Edelstein International Co., Ltd.”

You will find “Nothing we can’t Pack!”

EDELSTEIN INTERNATIONAL CO., LTD.

No. 396 Ta-tun 11th Street. Taichung 408, Taiwan

Tel: 886-4-22.51.55.06

Fax: 886-4-22.56.93.69

edel@ms36.hinet.net

• • •