Vacuum Filler

Negative Pressure Filling

Evacuation Filling Machine

These Vacuum Filling Machines are for all kind applications including wine, oil, beverage etc.

Looking for the vacuum filler for perfume pump bottle?

We have a particular model of vacum filler for perfume pump bottle

Perfume Vacuum Filler

Vacuum Filler

Negative Pressure Filling

Evacuation Filling Machine

After bottle rinsing machine, the containers like PP, PET or glass bottles, jar etc are transmitted to the bottle filler by means of transmission conveyor. The in-fed bottles from bottle washer are stand uprightly on the conveyor separately and individually by the feed-in star wheel of filling machine on to a Filling Platform of filler's turret. The filling platform of the filler rises and falls continuously during the filling turret rotating and the filler valve positioned above each container. The mouth of the container is pressed tightly with a pushed rubber seal ring before open the filling valve during filling. Against this rubber seal, the container mouth is completely tightened with filling nozzle to get the good air tight effect without any air leaking. The air inside of the container will be expelled out by means of a negative pressure device like piston or air blower offering the vacuum power which exists in the upper inner space of the container. The filling containers are rotating along with the platform of filler turret. At the same time, the opening between the rubber seal and filling nozzle is released by the raise of the bottle against the rubber seal, and filling product enters the bottle, due to low pressure existing in bottle. Once the filling product has risen to the level of the hole of the filling nozzle tube, no more air can be removed from the bottle, and the filling operation is terminated.

This type of filling has the advantages of rapid filling, reduced filling product losses.

If the mouth of the container is unexpected broken, the container cannot properly have perfect tight effect with rubber seal of filling nozzle, and filling product will not be filled in that bottle. This automatically reduces the product loss. The vacuum system also ensures foam free filling.

How the Vacuum Filler works:

A vacuum filler is a type of filling machine that is commonly used in the food and beverage industry to fill liquid products into containers. Here is how it works:

- Product is fed into the holding tank: The liquid product to be filled is fed into a holding tank, which is usually located above the filling machine.

- Container is placed on the filling nozzle: Empty containers are placed onto the filling nozzle of the machine.

- Vacuum is applied to the container: The machine then applies a vacuum to the container, which causes any air inside the container to be removed.

- Product is drawn into the container: Once the vacuum is applied, the filling valve is opened and the liquid product is drawn into the container. The vacuum helps to create a pressure difference, which allows the product to flow into the container.

- Filling valve is closed: Once the container is filled to the desired level, the filling valve is closed.

- Container is released from the filling nozzle: The filled container is then released from the filling nozzle and can be moved along the production line for further processing, such as capping or labeling.

Overall, the vacuum filling process helps to ensure that the containers are filled accurately and without any air bubbles or other impurities. This can improve the quality and shelf life of the product.

When the filling nozzle of the vacuum filling machine is inserted into the empty glass bottle, the sealing mechanism on the filling valve will cause a air-sealing effect on the bottle mouth, and then the air in the bottle will be drawn out through the vacuum device like vacuum pump, and then due to the pressure difference, all the The created vacuum naturally draws liquid through the filling valve and out into the bottle. When the inflowing liquid bottle reaches the preset filling level, the product will enter the filling valve nozzle and flow back out, into the return collection tank, where the product will be transferred back to the storage tank.

Vacuum Filler Models:

There is three types of vacuum filling machines for different productivity demands:

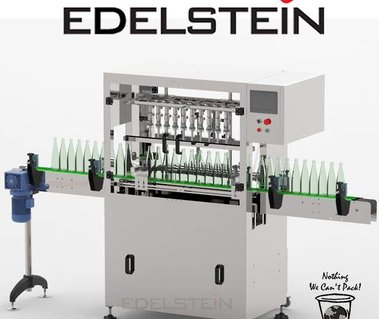

- Linear (In-Line) Vacuum Filler: for Medium Productivity

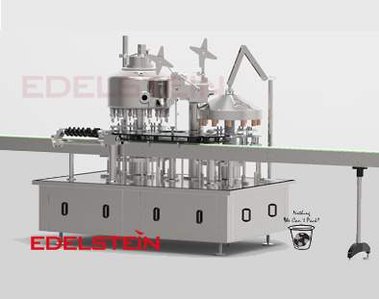

- Rotary: for High Productivity

- Manual (Bench-Top): for Low Productivity

Application:

Containers: Glass bottles

Products: Perfume, oil, vinegar, brine, syrup, sauce, wine, liquor, etc...

- Perfum Filler (Speciual for Perfume glass bottle filling) and Perfume Bottle Crimping Machine (Special for Perfume Cap enclosing)

Advantages:

- Through vacuum operated filling, the product is bottled in a most natural way, allowing to maintain its original quality and features.

- Product is filled without any contact between product and pumps or mechanical components.

How the negative pressure overflow Filler works?

A negative pressure overflow filler is a type of liquid filling machine that uses a special nozzle to fill containers with liquid products. The machine works on the principle of creating a vacuum in the container and then filling it with the liquid.

Here is a step-by-step overview of how the negative pressure overflow filler works:

- Container feeding: The containers are fed into the machine via a conveyor belt.

- Pre-evacuation: The containers are first evacuated by a vacuum to remove any air that may be present in the container. This is done to prevent foaming or air bubbles in the liquid product.

- Liquid filling: Once the containers are evacuated, the filling process begins. A special nozzle is used to create a vacuum in the container and simultaneously fill it with the liquid product.

- Overflowing: As the liquid fills the container, it overflows into a catch tray. The excess liquid is then recycled back into the holding tank for reuse.

- Post-filling: After the container is filled, the nozzle retracts and the vacuum is released. The container is then sent down the conveyor for further processing.

The negative pressure overflow filling method is commonly used for filling products that are prone to foaming or require precise filling levels, such as carbonated beverages, juices, and pharmaceuticals. The machine is designed to minimize product loss, ensure accurate filling levels, and maintain high production speeds.

How the Evacuation Filler works?

An evacuation filler is a type of filling machine that uses a vacuum to fill containers with liquid products. Here are the basic steps of how an evacuation filler works:

- Container Handling: The containers are first loaded onto the conveyor belt and move along to the filling station.

- Evacuation: Once the containers are in position, the filling process begins. The machine uses a vacuum to remove the air from the container, creating a negative pressure inside.

- Filling: With the air removed, the liquid product is forced into the container. The vacuum created in the previous step helps the liquid to flow into the container more quickly and efficiently.

- Pressure Equalization: After the container is filled to the desired level, the vacuum is released, and the container returns to atmospheric pressure. This helps to prevent the container from collapsing or deforming due to the pressure difference.

- Container Discharge: The filled container is then discharged from the filling station, and the process repeats for the next container.

The speed and efficiency of an evacuation filler depend on several factors, including the size and shape of the containers, the viscosity of the product, and the desired fill level.

What are the differences among Vacuum filler, Negative Pressure Overflow Filler and Evacuation Filler"?

The vacuum filler, negative pressure overflow filler, and evacuation filler are all types of liquid filling machines. However, they differ in their filling principles and operation and commonly used in the food and beverage industry.

A vacuum filler operates by creating a vacuum in the bottle or container to be filled. The product is then drawn into the container by the vacuum, with the excess product returning to the supply tank. The vacuum is then released and the filled container is removed. Vacuum fillers are typically used for filling non-carbonated liquids such as water, juice, and wine.

A negative pressure overflow filler, also known as a pressure gravity filler, works by filling the container from the bottom up. The container is placed on a platform and a filling valve opens to allow product to flow into the container. As the product level reaches the top of the container, it triggers a valve that shuts off the filling process. The excess product flows out of the container and back into the supply tank by gravity. Negative pressure overflow fillers are often used for filling carbonated and non-carbonated beverages.

An evacuation filler operates by first evacuating the air from the container and then filling it with the desired amount of product. The container is placed on a platform and a filling valve opens to allow product to flow into the container. As the product level reaches the top of the container, the filling valve shuts off and air is introduced back into the container, displacing any remaining product. Evacuation fillers are often used for filling products that are sensitive to oxygen, such as wine and other high-end beverages.

Overall, while there may be some similarities in the mechanisms of these fillers, their operating principles and applications are distinct.

“Looking for a Packaging machine”?

Just contact “Edelstein International Co., Ltd.”

You will find “Nothing we can’t Pack!”

EDELSTEIN INTERNATIONAL CO., LTD.

No. 396 Ta-tun 11th Street. Taichung 408, Taiwan

Tel: 886-4-22.51.55.06

Fax: 886-4-22.56.93.69

edel@ms36.hinet.net

• • •