Pressure Overflow Filler

Rotary Pressure Overflow Filler

for High productivity

In-Line Pressure Overflow Filler

for Medium productivity

Manual Pressure Overflow Filler

for Low productivity

PressureOverflow Filling Machine

The Pressure Overflow Filling Machine, madeby EDELSTEIN, is specially designed for

for low to medium viscosity liquids. Theoptimized engineered overflow nozzles guarantee that every container is filledto the same visual level.

The machine is manufactured with a 304stainless steel frame in in-line type or SS41 frame with anti-rust grinding,welding and powder coating covered in 2 mm T of SS304 sheet and is capable ofsupporting 2-12 or 12-50 fill heads on in-line model or rotary model. PLC controls, touch screen HMI,food grade contact parts, stainless steel and anodized aluminum construction.If is widely applied in the field of Food, Beverage, Chemicals, and Cosmeticproducts.

Product showroom:

Rotary Pressure Overflow Filler

for requirement of High productivity

Full Auto Operation

Continous running with non-stop bottle feeding and discharging

In-Line Pressure Overflow Filler

for requirement of medium productivity

Auto Operation

Continous running with batch bottles Intermittent feeding and discharging

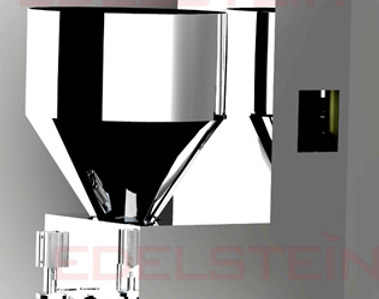

Manual Pressure Overflow Filler

for requirement of low productivity

Semi-Auto operation

Manual Bottles feeding and discharging

Pressure overflow filling is a type of liquid filling method that involves the use of a pressure tank to feed liquid into a container. In this method, the pressure tank is pressurized with air or another gas, which pushes the liquid out of the tank and into a filling nozzle. The filling nozzle is designed with an overflow tube, which allows excess liquid to flow back into the pressure tank.

As the liquid is fed into the container, it displaces the air in the container, creating a backpressure. When the backpressure is strong enough, the liquid level inside the container rises, and the excess liquid is diverted through the overflow tube back into the pressure tank. This overflow process is controlled by a level sensor, which maintains a constant liquid level inside the container.

Pressure overflow filling is often used for filling carbonated beverages or other liquids that require a precise fill level. The use of a pressure tank and overflow tube ensures that the fill level is consistent and accurate, even when filling at high speeds.

Pressure overflow filling can also be used for non-carbonated liquids. In this case, the liquid is pumped into the bottle at a higher pressure than the atmospheric pressure, and the excess liquid flows out of the bottle through the overflow tube. This method is used for filling containers with a consistent level of liquid, regardless of changes in temperature, viscosity, or other factors that may affect the volume of the liquid. It is commonly used for filling containers with products such as oils, sauces, and cleaning agents.clear

The key features of a pressure overflow filling machine for non-carbonated liquids are as follows:

- Accurate filling: The pressure overflow filling system ensures that the liquid is filled accurately to the desired level, minimizing the chances of underfilling or overfilling.

- Minimal product loss: The system minimizes product loss as it ensures that the liquid is filled to the exact level, preventing any spillage or overflow.

- Versatility: The system is versatile and can be used to fill different types of non-carbonated liquids, including viscous and foamy liquids.

- Easy to operate: The system is easy to operate and requires minimal training for the operator.

- Hygienic: The system is designed to meet hygienic standards, ensuring that the filling process is clean and the product is safe for consumption.

- High speed: The system is capable of filling a large number of bottles at a high speed, increasing the efficiency of the production line.

- Minimal maintenance: The system is designed to be durable and requires minimal maintenance, reducing downtime and increasing productivity.

Gravity Overflow Filling vs. Prssure Overflow Filling

Gravity overflow filling and pressure overflow filling are both commonly used for non-carbonated liquids. The main difference between them is the way the liquid is measured and controlled during the filling process.

In gravity overflow filling, the liquid is allowed to flow into the container by gravity, and the filling volume is controlled by the level of the liquid in the overflow tube. As the liquid rises to the top of the container, it flows into the overflow tube and back into the filler tank, ensuring a consistent fill level is achieved. The filling speed is controlled by the size of the filling valve orifice and the size of the overflow tube.

In pressure overflow filling, the liquid is pumped into the container under pressure, and the filling volume is controlled by the pressure in the filling tank. As the liquid reaches a predetermined height in the container, the pressure in the filling tank is released, causing the liquid to overflow into the overflow tube and back into the filler tank. The filling speed is controlled by the pressure in the filling tank and the size of the overflow tube.

Overall, pressure overflow filling is typically faster and more precise than gravity overflow filling, as it allows for more control over the filling volume and speed. However, it may be more expensive to set up and maintain, as it requires more complex equipment and additional pressure control systems. Gravity overflow filling, on the other hand, is simpler and more cost-effective, but may not be suitable for high-speed or high-precision filling applications.

“Looking for a Packaging machine”?

Just contact “Edelstein International Co., Ltd.”

You will find “Nothing we can’t Pack!”

EDELSTEIN INTERNATIONAL CO., LTD.

No. 396 Ta-tun 11th Street. Taichung 408, Taiwan

Tel: 886-4-22.51.55.06

Fax: 886-4-22.56.93.69

edel@ms36.hinet.net

• • •