Screw Capper

thread capper

Chuck Screw Capper

Chuck thread capper

A Capper with chuck capping head for closing the screw cap

- In-line Chuck Screw Capping Machine

- Rotary Chuck Screw Capping Machine

- Manual Table-top Chuck Screw Capping Machine

A bottle capping machine with chuck type capping head gripping the cap. The gripping power generated from the chuck picks from cap chute and places the cap on the bottle mouth, and then tighten the screw of cap onto a bottle.

It's important to choose the proper and correct type and size of chuck to tighten the cap.

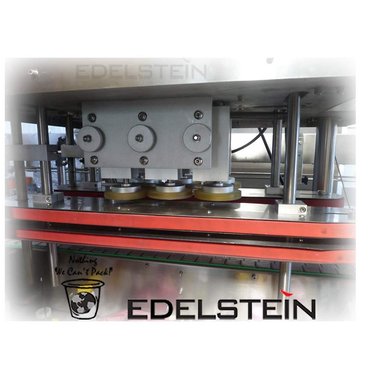

Spindle (Roller) Screw Capper

Spindle (Roller) Screw Capping Machine

A Capper with Spindle (Roller) capping head for closing the screw cap

- In-line Spindle (Roller) Screw Capping Machine

- Rotary type Spindle (Roller) Screw Capping Machine

- Manual Table-Top Spindle (Roller) Screw Capping Machine

Multi-Spindle Screw Capper

Multi-Spindle Screw Capping Machine

A Capper with Multi-Spindle (Mulit-Roller) capping head for closing the screw cap

- In-line Multi-Spindle Screw Capping Machine

- Rotary (not available)

- Manual Table-Top (not available)

Claw Screw Capper

Claw type Screw Capping Machine

Gripper type Screw Capping Machine

A Capper with Claw (Gripper) capping head for closing the screw cap

- In-line Claw Screw (Gripper) Capping Machine

- Rotary Claw Screw (Gripper) Capping Machine

- Manual Table-Top Claw (Gripper)Screw Capping Machine

A bottle capping machine with claw type capping head clamping the cap. The clamping power generated from the claw picks from cap chute and places the cap on the bottle mouth, and then tighten the screw of cap onto a bottle.

It's important to choose the proper and correct type and size of claw to tighten the cap.

The application range is relatively wide for large size and also various different sizes of caps on one claw capping head.

Snap Screw Capper

Snap type Screw Capping Machine

A Capper with Snap capping head for closing the screw cap

- In-line Snap Screw Capping Machine

- Rotary Snap Screw Capping Machine

- Manual Table-Top Snap Screw Capping Machine

The application range is relatively wide for large size and also various different sizes of caps on one claw capping head.

Screw caps, also known as threaded caps, are commonly used in the packaging industry to seal bottles, jars, and other containers. Screw capping machines are specifically designed to apply screw-on caps to containers. In this article, we will explore the different types of screw capping machines and their characteristics and functions.

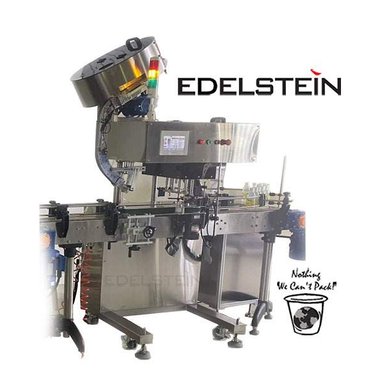

- Automatic Screw Capping Machine

Automatic screw capping machines are designed for high-speed production lines. They are fully automated and can apply screw-on caps to bottles, jars, and other containers quickly and efficiently. These machines are equipped with sensors that detect the container and cap, ensuring accurate and consistent capping. They are ideal for large-scale production lines and can handle a variety of cap sizes and shapes.

- Semi-Automatic Screw Capping Machine

Semi-automatic screw capping machines are designed for small to medium production lines. They require an operator to manually place the container under the capping head and activate the machine. The machine then applies the cap and releases the container. These machines are easy to use and require minimal maintenance. They are ideal for smaller production lines that require consistent and accurate capping.

- Handheld Screw Capping Machine

Handheld screw capping machines are designed for low-volume production or manual operations. They are lightweight and portable, allowing operators to move around the production area easily. These machines are easy to use and require minimal maintenance. They are ideal for small production lines, mobile operations, or as a backup capping machine.

- In-line Screw Capping Machine

Inline screw capping machines are designed for use with conveyor systems. They can be integrated into an existing production line, ensuring consistent and efficient capping. These machines are ideal for high-volume production lines that require continuous capping. They are equipped with sensors that detect the container and cap, ensuring accurate and consistent capping.

Rotary screw capping machines are designed for high-speed production lines. They are equipped with multiple capping heads that rotate around a central turret, applying caps to containers as they pass by. These machines can handle a variety of cap sizes and shapes and are ideal for large-scale production lines that require consistent and accurate capping.

In conclusion, screw capping machines are an essential part of the packaging industry. They are designed to apply screw-on caps to bottles, jars, and other containers quickly and efficiently. Choosing the right screw capping machine depends on the production line speed, the type of container and cap, and the operator experience. By understanding the different types of screw capping machines and their characteristics and functions, manufacturers can choose the best capping machine for their packaging needs.

Regarding in-line screw capping machine (linear type screw capping machine) or manual type screw capping machine, there are a couples of different mechanical structural designs to meet the demand of screwing the caps on the bottles.

In-Line Screw Capping Machines:

- Spindle Capping Machines

Spindle capping machines are the most commonly used in-line screw capping machines. They use a rotating spindle to apply the screw caps to bottles. The bottles are held in place by a conveyor belt or an indexing table, and the spindle applies torque to the caps, tightening them onto the bottles. These machines can handle a wide range of cap sizes and are suitable for high-speed production lines.

- Chuck Capping Machines

Chuck capping machines use a chuck to hold the cap in place while the bottle is rotated, tightening the cap onto the bottle. They are commonly used for smaller bottle sizes and are ideal for capping delicate or fragile containers. Chuck capping machines are slower than spindle capping machines, but they provide more precise torque control.

- Snap Capping Machines

Snap capping machines use a pressing mechanism to apply snap-on caps to bottles. They are commonly used for plastic bottles and are ideal for low- to medium-speed production lines. Snap capping machines are simple to operate and require minimal maintenance.

Manual Screw Capping Machines:

- Handheld Capping Machines

Handheld capping machines are manually operated and are designed for low-volume production or manual operations. They are lightweight and portable, allowing operators to move around the production area easily. These machines are easy to use and require minimal maintenance. They are ideal for small production lines, mobile operations, or as a backup capping machine.

- Benchtop Capping Machines

Benchtop capping machines are manually operated and are designed for small to medium production lines. They are compact and can be placed on a workbench or table. These machines use a lever or handwheel to apply torque to the cap, tightening it onto the bottle. Benchtop capping machines are easy to use and require minimal maintenance.

- Pneumatic Capping Machines

Pneumatic capping machines use compressed air to apply torque to the cap, tightening it onto the bottle. These machines are ideal for medium- to high-speed production lines and can handle a variety of cap sizes and shapes. Pneumatic capping machines are easy to operate and require minimal maintenance.

In conclusion, in-line screw capping machines and manual screw capping machines are designed to apply screw-on caps to bottles and other containers quickly and efficiently. Choosing the right screw capping machine depends on the production line speed, the type of container and cap, and the operator experience. By understanding the different types of in-line screw capping machines and manual screw capping machines and their characteristics and functions, manufacturers can choose the best capping machine for their packaging needs.

If you are not sure which type you should select or you need professionally technical consultation, please contact us, we will provide you with the most suitable solution according to your actual needs.

“Looking for a Packaging machine”?

Just contact “Edelstein International Co., Ltd.”

You will find “Nothing we can’t Pack!”

EDELSTEIN INTERNATIONAL CO., LTD.

No. 396 Ta-tun 11th Street. Taichung 408, Taiwan

Tel: 886-4-22.51.55.06

Fax: 886-4-22.56.93.69

edel@ms36.hinet.net

• • •