Piston Filling

Applied containers can be divided into bottles, cups, tubes etc.

Most of the filled contents are highly viscous liquids which other filling methods are mainly adapted when the speed and accuracy cannot be satisfied. (ex. peanut butter, butter, chocolate sauce, dressings etc.)

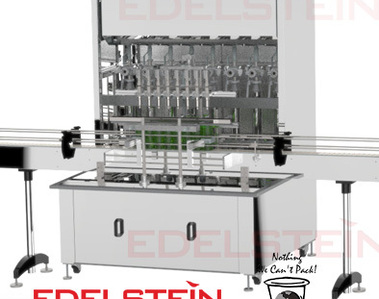

Bottle Piston Filler

Piston Filling System applied on Bottle Packaging Machine

Cup Piston Filler

Piston Filling System applied on Cup Packaging Machine

Bag Piston Filler

Piston Filling System applied on Bag Packaging Machine

Tube Piston Filler

Piston Filling System applied on Tube Packaging Machine

The type of piston filling machine can be divided into pneumatic, cam, servo, etc. according to the driving method.

Pneumatic Piston Fillers:

This type of piston driving filling system is mostly used for filling wide-open containers (jar, pail, wide mouth bottle) or tube with relatively high viscosity fluids like gels, sauces, creams etc. To operate this pneumatic piston filling system needs additional compressed air. The machine movement of the method is the cylinder runs in reciprocating and linear motions to drive the piston and generate the suction and thrust which draws and pushes the liquid.

A limitation of pneumatic piston fillers is that their speed profile is fixed throughout the cycle.

If the product you're filing foams or splatters easily, or if your containers are unevenly shaped (ex. most of sauce bottles with taper at the top ), it will be not proper choice to apply pneumatic piston fillers. It will be more wise to adapt servo driven or rotary piston filler with mechanical cam piston filling system.

Servo Piston Fillers:

To minimize the issues of accuracy and speed for Pneumatic Piston Fillers, EDELSTEIN's Servo Piston Fillers is available for different applications and request.

Cam Piston Fillers: (Rotary Piston Fillers)

Rotary filler with the customized designed rotary piston filling system can be primary considered to apply. Our rotary piston filling machine can be manufactured with 12 to 32 filling stations (filling nozzles). The filling system is mechanical cam structure as standard. All machines come with machine warranty with proven reliability.

Applications:

- Semi-viscous and viscous liquids

- Pasted like slolutions

- Dressings

- Chocolate sauce

- Marmelada

- Peanut butter

- Butter

- Catchup

- Mustard

- Syrups

- Salsa

- Mayonnaise

- Lip balm

- Jellies

- Dipping sauces

- Shampoo

- Thick soaps

- Styling gels

- Facial masks

- Wax

- Glue

- Grease

- Sealants

- Silicone

About Piston Filler:

Any filling machine has more or less precision problems. As for the most widely used and simple structure, but most of the requirements are met in terms of capacity accuracy requirements. Let's discuss the problem of filling accuracy in the piston filling machine. Under what circumstances, the filling accuracy of the piston filling machine may not meet the requirements. The following possible reasons will cause the accuracy of the piston filling machine to be inaccurate:

First of all, it is necessary to confirm the type of piston filling machine selected. Usually, the types of piston filling machines are generally the same in principle, but because of the difference in production speed, there are desktop manual or semi-automatic piston filling machines, most of which are driven by a single piston cylinder and a single filling valve. Most of the methods are to use the simplest and most convenient air pressure system to push the piston with the air cylinder. If the production speed is medium, a linear piston filling machine is usually used, and the most common type of this linear piston filling machine is to use a pneumatic cylinder to push the piston.

For the piston filling model where the pneumatic cylinder pushes the piston, the air in the fluid line may not be completely emptied because the fluid channel used is actually used, so in the same piston push-out stroke, the piston The liquid in the cylinder or the tube of the fluid passage is not full, and the liquid discharged is not enough. In this case, as long as the pipe is exhausted and the piston is discharged several times, the filling result with normal accuracy can be obtained.

In addition, the phenomenon that may be encountered is that the three-way valve switched between the storage tank, the piston and the filling valve, because some factors cause the action of the switching valve to be incorrect. It may be that the air pressure is insufficient, or there are foreign objects in the valve, so the switch of the valve is not completely switched, and then the filling production will be carried out after the maintenance and repair methods for the insufficient air pressure and the removal of foreign objects.

In order to increase the production speed, this kind of piston filling machine driven by air pressure can be used mostly from 2 piston cylinders to 16 piston cylinders, and even double-row filling valves can be used for speed. However, due to the limitations of the linear structure, the number of piston cylinders should not be too large, because the efficiency will not be very good. This is because the container refilling machine has time to go in and out. If there are too many filling piston cylinders, it will take more time to go in and out of the filling area, which is not practical.

In addition, the piston filling with a larger container will allow the filling machine to use a larger diameter and longer piston stroke to meet the production requirements, but this will increase the filling time a lot, and the size of the large container is larger, and it will also increase the filling time. It will take time to get in and out of the filling machine, which must also be considered.

More importantly, due to structural factors, there are usually differences in the capacity of each piston cylinder, which is why the filling capacity is inaccurate.

How to reduce this inaccurate filling situation? First of all, there must be experience in the mechanical structure to achieve good rigidity. In addition, an advanced servo drive system can be used to drive the piston with a precision ball screw, replacing the commonly used pneumatic cylinder.

However, this servo-driven piston cylinder filling machine still has a difference in the capacity of each piston cylinder, resulting in inaccurate filling capacity. Therefore, another more exquisite method is that each piston cylinder is driven by an independent pneumatic cylinder, or a more precise method is that each piston cylinder is equipped with a servo motor and a precision ball screw, so that the capacity of each piston can be adjusted. Can be finely tuned.

For faster production speeds, consider a rotary piston filling machine. This rotary piston filling machine is also widely used in higher production lines and has been used in many industrial fields for a long time. Because it adopts the cam-type mechanical structure, it can have very stable machine operation performance.

Designing an optimum rotary type piston filler to meet the demand of desired filling volume and production speed would require a comprehensive approach. Here are some factors to consider in the design process:

- Piston Size and Stroke Length: The piston size and stroke length must be carefully selected to ensure accurate filling of desired volume. The piston size should be large enough to fill the required volume, and the stroke length should be adjusted accordingly to minimize cycle time. With relative fewer filling stations, the piston size and stroke length should be carefully selected to ensure accurate filling of higher volume at each station. The piston size and stroke length can be adjusted to achieve the required filling accuracy and minimize cycle time.

- Number of Filling Stations: The number of filling stations should be determined based on the desired production speed. The number of stations can vary from 8 to 24, even more than 32, depending on the required cycle time and filling accuracy.

- Filling Speed and Flow Control: The filling speed should be set to achieve the required production speed while ensuring accuracy and consistency. The flow control system should be designed to prevent overfilling or underfilling.

- Material Handling System: The design of the material handling system should be optimized to minimize downtime and maximize efficiency. The system should be capable of handling containers of different shapes and sizes. The system should minimize any vibrations or shocks that could affect filling accuracy. For some kind viscous fluid like peanut butter, chocolate sauce or gel, the use of specialized pumps or gear pumps may be necessary to ensure consistent and accurate filling.

- Cleaning and Maintenance: The filler should be easy to clean and maintain to ensure product quality and minimize downtime.

- Automation: The filling machine should be automated to increase production efficiency and reduce the need for manual intervention.

- Quality Control: Quality control measures, such as automatic rejection of faulty bottles, should be incorporated to ensure product quality.

For some food grade applications:

- Material Contact Surfaces: All parts that come into contact with the chocolate sauce should be made of food-grade materials, such as stainless steel, that are easy to clean and maintain. The material contact surfaces should be designed to prevent product buildup and ensure hygienic filling.

For some temperature request:

Temperature Control: The chocolate sauce should be kept at a consistent temperature to prevent solidification or separation during the filling process. The filler can be designed to incorporate temperature control mechanisms to maintain the product at the required temperature.

Optional Accuracy and Quality Control strategy:

- Automated Quality Control: The rotary type piston filler can be designed with an automated quality control system to detect and reject any bottles that are not filled accurately. The system can be programmed to reject bottles that fall outside the desired filling accuracy range.

- Checkweigher: A checkweigher can be installed after the filling process to ensure that each bottle has been filled accurately. The checkweigher can be programmed to reject any bottles that do not meet the required filling accuracy range.

- Real-Time Monitoring: The filling machine can be designed to include real-time monitoring of the filling process to detect any issues and prevent defective products from reaching the market.

Overall, designing an optimum rotary type piston filler to meet the demand of desired filling volume and production speed requires a comprehensive approach that takes into account the factors mentioned above. It is important to work closely with experienced engineers and manufacturers to ensure that the design meets the required specifications and regulatory standards.

“Looking for a Packaging machine”?

Just contact “Edelstein International Co., Ltd.”

You will find “Nothing we can’t Pack!”

EDELSTEIN INTERNATIONAL CO., LTD.

No. 396 Ta-tun 11th Street. Taichung 408, Taiwan

Tel: 886-4-22.51.55.06

Fax: 886-4-22.56.93.69

edel@ms36.hinet.net

• • •