Home > Sorting > Bottle Sorting > Linear Bottle Unscrambler

Linear Type Bottle Unscrambling Machines

Rotary Disk Type Bottle Unscrambler

Bottle Sorter

Bottle Sort, Orient and Feed

In-line bottle unscrambler

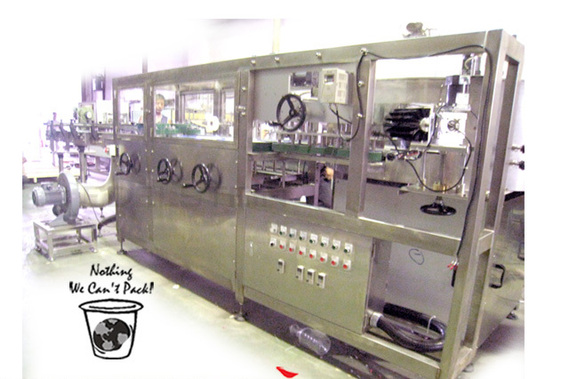

In-line bottle unscrambler including bottle storage tank, sorter and orientation feeder made by Edelstein to coordinate with related filling & capping systems as a automaton line. The unscrambler is equipped with vacuum system especially to have much stable loading motion for light PET bottle in high speed movement. Dual belt transmission design is friendly adjusting for different bottle width without extra spare parts required and is ideal to be applied in the field of Beverage, Chemicals, Cosmetics, Beauty and Household products.

Bottle unscrambler with bottle storage tank, sorter and orientation feeder made by Edelstein to coordinate with related filling, sealing & capping systems as a automaton bottling line to be applied in the field of Beverage, Chemicals, Cosmetics, Beauty and Household products.

A versatile range of bottle unscramblers that allow multiple container formats to be carefully sorted and orientated in a single machine system.

EDELSTEIN'S bottle unscrambling machines (Bottle Sorting Machines) are designed to offer an perfect combination of quality, reliability and precision.

The complete bottle unscrambler indcluding:

- Cotainer Storage Tank with orintation function

- Bottle Feeding conveyor

- Bottle Sorting device

- Bottle discharge deivce

Applications of the complete range of various type of bottles:

- Softdrink Bottles

- Food stuff Bottles

- Personal care products

- Hygienic containers

Linear Tyep Bottle Unscrambler (Rotary Disc Bottle Unscrambler):

It is a traditional and widely used type of bottle unscrambler in the packaging industry. Here's a comprehensive overview of the Rotary Disc Bottle Unscrambler, including its operation, advantages, limitations, and orientation concept:

Rotary Disc Bottle Unscrambler:A Rotary Disc Bottle Unscrambler is a bottle sorting and orienting machine that utilizes a rotary disc and mechanical guides to separate, orient, and align bottles before further processing. It provides a controlled and efficient flow of bottles for packaging lines.

Operation:

- Bottle Loading: Bottles are initially loaded into a bulk storage tank.

- Rotary Disc: The rotary disc at the bottom of bottle bulk storage tank is not equipped with pockets or cavities like rotary type bottle unscramble. Instead, the rotary disk rotates continuously, creating a controlled flow of bottles to make the bottle feed the tank.

- Bottle Extraction: As the rotary disc rotates, mechanical guides extract the bottles from the bulk storage tank and position them horizontally.

- Transfer Belt: A transfer belt or conveyor receives the horizontally positioned bottles from the rotary disc and transports them to the orientation device.

- Orientation Device: The orientation device, often equipped with hooks or similar mechanisms, manipulates the bottles to ensure they face the desired direction.

- Bottle Rotation: The bottles undergo a rotation process facilitated by the orientation device, aligning them to stand upright on the conveyor.

- Conveyor Delivery: The properly oriented bottles are then transferred to the packaging line for further processing.

Advantages:

- High Speed: Rotary Disc Bottle Unscramblers are capable of handling high-speed production lines, offering efficient bottle sorting and orientation.

- Versatility: They can handle a wide range of bottle sizes and shapes, providing flexibility for various packaging applications.

- Reliable Operation: Rotary Disc Unscramblers are known for their reliability and consistent performance, ensuring a smooth and continuous bottle flow.

Limitations:

- Changeover Time: Switching between different bottle sizes or shapes may require adjustments to the mechanical guides and orientation device, resulting in increased changeover time.

- Space Requirements: Rotary Disc Unscramblers typically have a larger footprint compared to other unscrambler types, requiring sufficient space in the production area.

Orientation Concept:The Rotary Disc Bottle Unscrambler utilizes a combination of rotary motion, mechanical guides, and an orientation device to separate, position, and align the bottles. The rotary disc extracts the bottles from the bulk storage tank, positioning them horizontally. The transfer belt transfers the bottles to the orientation device, which manipulates them to face the desired direction. The orientation device further rotates the bottles, ensuring they stand upright on the conveyor for downstream processing.

In summary, the Rotary Disc Bottle Unscrambler is a widely used and reliable solution for bottle sorting and orientation. Its high-speed capabilities, versatility in handling different bottle sizes and shapes, and consistent performance make it suitable for a wide range of packaging applications. While changeover time and space requirements may be considerations, the Rotary Disc Bottle Unscrambler remains a valuable tool for optimizing bottle flow in packaging lines.

Why is the bottle uncsrambler necessary used for bottling line?

Aiming at the demand of bottle unscrambling machine, this is because in the process of bottling production line, the empty bottles will be put into the production process of bottle rinsing, filling and capping first, but usually the empty bottles enter the filling machine and capping machine through the conveyor The state of these bottles conveyed into these bottling machines are accepted as specific position and orientation, at least the bottles must be standing instead of dumped and scattered on the conveyor belt. However, a large amount of empty bottles will be manually placed and stood on the conveyor belt, which is indeed a very large manpower load. Therefore, if the normal production speed is used, the automatic bottle unscrambling method will be adopted instead of manual placement, so that the whole batch of scattered bottles can be automatically and sequentially stood on the conveyor belt through the automatic bottle unscrambling machine. The sequence enters into the bottle washing machine, filling machine, capping machine and other bottle equipment for production.

Are you intertested in Acuumulation Tables?

Home > Sorting > Bottle Sorting > Linear Bottle Unscrambler

“Looking for a Packaging machine”?

Just contact “Edelstein International Co., Ltd.”

You will find “Nothing we can’t Pack!”

EDELSTEIN INTERNATIONAL CO., LTD.

No. 396 Ta-tun 11th Street. Taichung 408, Taiwan

Tel: 886-4-22.51.55.06

Fax: 886-4-22.56.93.69

edel@ms36.hinet.net

• • •