HOME > Bottling > Bottling Line > PET Bottled Water Bottling Line

PET Bottled Water Bottling Line

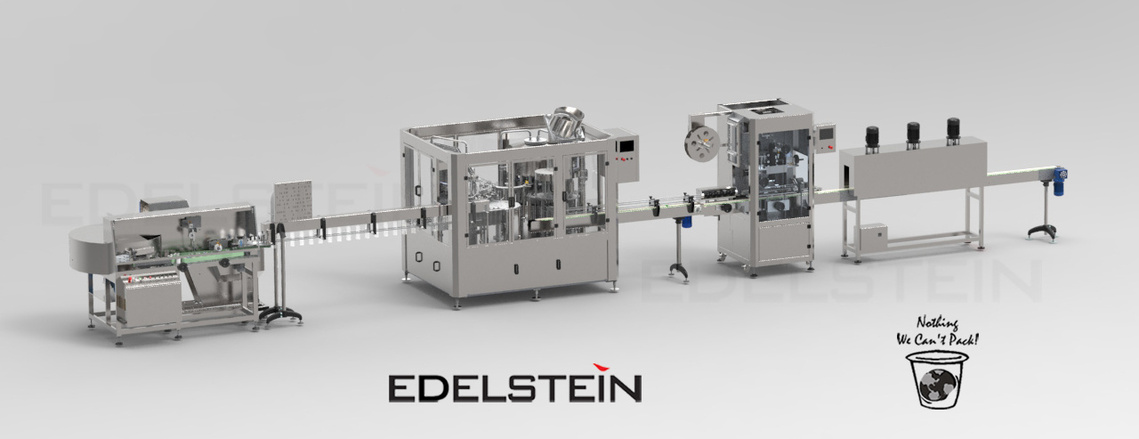

PET Bottle Filling Line for Drinking Water: Bottle Unscrambler + Rotary Bottle Rinsing-Filling-Screw Capping Machine + Bottle Shrink Labeling Machine

Crafting Excellence: Unveiling the PET Bottled Water Production Line

Introduction

In today's world, where hydration is essential, the demand for bottled water continues to surge. Meeting this demand efficiently and maintaining the highest quality standards necessitates a state-of-the-art PET Bottled Water Production Line. Whether you're filling popular bottle sizes like 330ml, 500ml, 750ml, and 1000ml, precision and reliability are paramount. Join us on a journey through the PET Bottled Water Production Line, where we explore the features and functions of each essential piece of equipment, ensuring your bottled water meets the highest industry standards.

Essential Equipment in the PET Bottled Water Production Line

1. Bottle Unscrambler: Efficient Arrangement for a Smooth Start

At the heart of the PET Bottled Water Production Line lies the Bottle Unscrambler. This essential equipment ensures a seamless beginning to the production process. Bottles are fed into the unscrambler, which arranges them uniformly, preparing them for the journey ahead. It's the first step towards a consistently efficient production line.

2. Monoblock Rotary Bottle Rinsing-Filling-Screw Capping Machine: Precision at Its Core

The Monoblock Rotary Machine is the workhorse of the production line. It's a multi-tasking marvel that integrates three vital functions:

Bottle Rinsing: Before filling, bottles are meticulously rinsed, eliminating any contaminants. This step is crucial for ensuring the purity of your bottled water.

Equal-Level Filling: Precision is the key when it comes to filling. The equal-level filling method guarantees that each bottle receives the exact designated volume of water, maintaining product consistency.

Screw Capping with Torque-Limited Clutch: To seal the deal, the machine employs a chuck capper with a torque-limited clutch. This ensures that each bottle is securely capped, preventing leaks and tampering.

3. Bottle Shrink Labeling Machine: Sleek and Informative

The Bottle Shrink Labeling Machine adds a touch of branding and product information to your bottled water. This equipment expertly applies shrink labels to the bottles, providing vital product details and enhancing the visual appeal of your product. It's the finishing touch that sets your bottled water apart on the shelves.

4. Group Packing Machine: Efficiency in Packaging

The Group Packing Machine is the final piece of the puzzle. It efficiently packages your bottled water, creating bundles or packs suitable for distribution. This equipment streamlines the packaging process, ensuring that your products are ready for delivery to retailers or consumers.

Features and Functions:

- Efficiency and Precision: The PET Bottled Water Production Line operates with unrivaled efficiency and precision. The integration of multiple functions into the Monoblock Rotary Machine minimizes handling and maximizes accuracy.

- Versatility: This production line accommodates the most popular bottle sizes, from 330ml to 1000ml, offering versatility to adapt to changing market demands.

- Equal-Level Filling: The equal-level filling method guarantees that each bottle receives the exact designated volume of water, eliminating inconsistencies and ensuring product quality.

- Torque-Limited Clutch: The chuck capper with a torque-limited clutch guarantees secure and consistent capping, maintaining the integrity of your bottled water.

- Hygiene and Quality: Bottle rinsing and strict hygiene controls throughout the line ensure the highest product quality and safety standards are met.

- Branding and Aesthetics: The Bottle Shrink Labeling Machine adds branding and informative labels to enhance your product's visual appeal and consumer communication.

- Efficient Packaging: The Group Packing Machine streamlines the packaging process, making your products ready for distribution efficiently.

- Air Blowing Conveyor: The air blowing conveyor efficiently connects the Bottle Unscrambler to the Bottle Rinsing Machine, ensuring smooth bottle transfer while minimizing contamination risks.

Conclusion

The PET Bottled Water Production Line is a symphony of efficiency, precision, and quality. From the Bottle Unscrambler to the Monoblock Rotary Machine, Bottle Shrink Labeling Machine, and Group Packing Machine, each piece of equipment plays a vital role in crafting the perfect bottled water product.

As you embark on your journey in the bottled water industry, this production line ensures that your products not only meet but exceed industry standards. With versatility in bottle sizes, precision in filling and capping, and the added touch of branding and efficient packaging, you're poised to make a splash in the world of bottled water.

Invest in the PET Bottled Water Production Line, and let excellence flow from your production line to the hands of your consumers, one perfect bottle at a time.

EDELSTEIN offers water Bottling Line equipment for various container sizes

Whatever bottled water inclding still water, sparkling water produced, EDLSTEIN's bottling machines are perfect forany production line to meet the requirement of high performance and low cost.

0.25L, 0.33L, 0.35L, 0.5L, 0.6L, 0.75L, 1.5L, 2.0L water bottles.

Our Bottling production line equipment (Bottling Line Machines) covers Bottle Unscrambling Machines, Bottle Rinsing Machines, Bottle Filling Machines, Bottle Capping Machines, Bottle Aluminum Foil Sealing Machines, Cap Sorting Machines, Bottle Warming Machines.

If you are not sure which type you should or you need professionally technical consultation, please contact us, we will provide you with the most suitable solution according to your actual needs.

HOME > Bottling > Bottling Line > PET Bottled Water Bottling Line

“Looking for a Packaging machine”?

Just contact “Edelstein International Co., Ltd.”

You will find “Nothing we can’t Pack!”

EDELSTEIN INTERNATIONAL CO., LTD.

No. 396 Ta-tun 11th Street. Taichung 408, Taiwan

Tel: 886-4-22.51.55.06

Fax: 886-4-22.56.93.69

edel@ms36.hinet.net

• • •